Description

Check valve is a one-way valve allowing fluid to flow through one opening and leave through the other.

The general purpose of this valve is to prevent backflow (flow in the opposite direction).

Check valves inherit the term “cracking pressure”. When the cracking pressure is reached, the valve will open. When the pressure drops below the cracking pressure and/or back-pressure occurs, the valve closes. The way a Check valve operates is ideal for preventing contamination from fluid flowing into separate services connected to a common header. This valve works automatically, and typically with no human or external control, such as a valve handle or stem.

Check valves have different configurations with the most common being the swing, tilting-disc, wafer, lift, and stop-check valves.

Application

The swing check valves are used as check valves for oil & gas, petrochemical, power, offshore and other demanding applications. These valves will not allow the flowing of the fluid in reverse direction than that indicated by the arrow. A wide choice of shell and trim materials do cover the whole range of applications, from the every-day type of non-corrosive service to critical service with highly aggressive media.

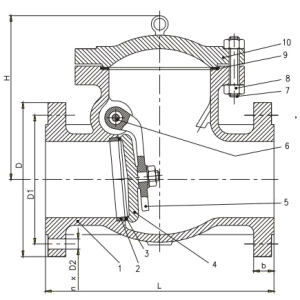

Constructive and functional characteristics

- type: bolted cover

- flanged ends

- mounting position: horizontal, taking care of the flowing direction indicated by arrow

- free stroke

Execution

- basic design according to BS 1868

- face to face according to ANSI B16.10

- flanges according to ANSI B16.5

- flange facings 0.06″ raised face for class 150; 300 and 0.25″ for class 600

- pressure – temperature ratings according to ASME B16.34

- shell wall thickness according to API 600(hydrostatic seat test)

- trim standard: trim 1 main sealing 13% Cr / 13% Cr

On request

- other shell materials (Carbon steel, Stainless steel, Monel, Duplex, Inconel)

- other trim

- other flange facings according to ANSI B 16.5 or B/W ends to ANSI B16.25

- other type gasket body – bonnet

- lantern ring for class 300

- drain tappings

- by-pass

- manufactured according to specification NACE MR 0175 for hydrogen sulphide and sour gas service